Subsea Cable Maintenance & Repairing: Improving Reliability and Avoiding Downtime

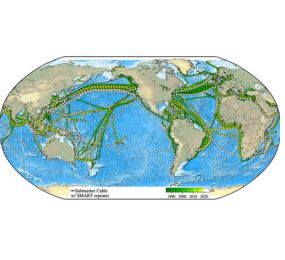

As the world becomes more reliant on subsea cables for data transmission and offshore energy operations, so are these thousands of miles of long cables strung out along the ocean floor in the backbone for internet connectivity and power delivery. Submarine cable damage and repair remain the most formidable challenge and usually come at a high cost in terms of downtime and unavailability of certain services. Thus, maintenance strategies for subsea cables are changing through the introduction of advanced technology and proactive planning to maintain uninterrupted operational performance.

The Growing Need for Subsea Cable Maintenance

Most of the data around the globe is carried by subsea cables connecting the various continents for internet and international radio connectivity as well as for connecting offshore energy grids to shore. However, their physical robustness notwithstanding, damage to these cables can occur due to natural calamities, fishing activities, and shipping operations. TeleGeography estimates that there are more than 100 cable faults globally each year – each capable of disrupting major areas.

That is why proactive subsea cable maintenance is important for minimising such outages. It could be accomplished using regular inspections, predictive analytics, and advanced monitoring technologies that detect early signs of wear or damage to prevent expensive failures.

The Causes of Damage to Submarine Cables

Identifying these initial causes is the first step towards implementing effective maintenance and repair strategies. The following are the major causes:

- Fishing with Anchoring: More than half of the damage to cables is from fish nets and anchors of ships, leaving shallow waters very susceptible.

- Natural Occurrences: Earthquakes, landslides, and ocean flows can cause notable physical damage to the cables.

- Human Error: Faults and breaks may occur as a result of accidents during submarine cable installation works or offshore drilling activities.

- Marine Animals: To the surprise of most people, even sharks are known to gnaw fibre optic cables just because they are attracted to electromagnetic fields.

Case Study: Restoring a Critical Link

A very exciting example of quick and effective repair was the major transatlantic cable that broke near Iceland in 2022 on account of seismic activity, with the outage extending across parts of Northern Europe. The cable was repaired within fourteen days with the deployment of an advanced cable repair vessel equipped with remotely operated vehicles; this is considerably shorter than the average repair time of 4-6 weeks.

It highlighted the need to have specific repair agreements and pre-positioned spare parts at high-risk areas to speed up the restoration process.

Innovative Approaches to Subsea Cable Maintenance and Repair

- ROVs and AUVs: These sophisticated machines peer into cables, search for failures, and help their operations in the presence of a human diver.

- Predictive A.I. Maintenance: Cable sensors provide a window into the understanding by analysing data for the determination of faults with early intervention before they affect the functioning of the system.

- Self-healing Cables: It excels in rerouting data around damaged fibres, thus improving turnaround times before complete repairs are made.

- Modular Cable Designs: Simplified structures make on-site faster and cheaper repairs.

Offshore Transmission Conference: Leading the Future of Subsea Cable Management

The conference is hosted by Leadvent Group and is undoubtedly the most bustling activity for meeting leading stakeholders in the energy and telecommunications sectors who might be interested in bringing revolutionary efficiency into the submarine cable maintenance and submarine cable installation processes.

Why Attend the Offshore Transmission Conference?

- Expert Knowledge: Hear from top engineers, innovators, and policymakers new techniques to avoid damages and delays of repairs in submarine cables.

- Technology Showcases: Cutting-edge solutions, including AI diagnosis, deep-sea ROV technology, and sustainable cable materials.

- Guaranteed Networking Opportunities: Meet world-renowned experts with subsea cable operators and investors in infrastructure to form an all-important engagement.

- Case Studies and Panels: Real examples present the merits of rapid response repair as well as preventative maintenance.

Case Study: Offshore Wind Power Grid Expansion

The Offshore Transmission Conference placed its spotlight on a revolutionary work: the integration of high-capacity subsea cables into offshore wind farms in Northern Europe. Operators talked about how to cope with fair detrimental weather conditions, brought down their repair time by forty per cent, and increased the stability of their grids.

FAQs

1. What is the frequency of inspection for subsea cables?

It is highly recommended to have an inspection every 6-12 months for a platform along with continuous sensor-based monitoring to detect anomalies.

2. How much downtime does a submarine cable damage have on average?

Conventional repairs take 4-6 weeks to complete. New technologies such as ROVs and pre-deployed repair kits have considerably reduced this time.

3. What's in it for my business by attending the Offshore Transmission Conference?

This form of networking provides exclusive insight into new solutions while meeting fellow businesspeople and, as a bonus, learning how other companies conduct their operations regarding subsea cables.

Stay Connected: Future-Proof Your Subsea Cable Network

There is a burgeoning, voracious demand for high-speed data and renewable offshore energy, and subsea cables are increasingly becoming the lifelines enabling that transformation. Without proactive Submarine cable damage and repair, costly outages lost revenues, and weakened infrastructure face organisations.

Join the Offshore Transmission Conference and lead the charge in building a more resilient, reliable, and efficient subsea infrastructure.