Strategies for Recovering and Reprocessing Critical Battery Materials

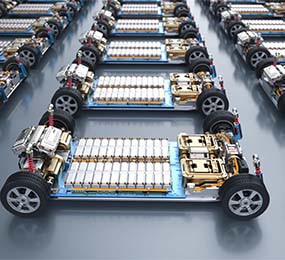

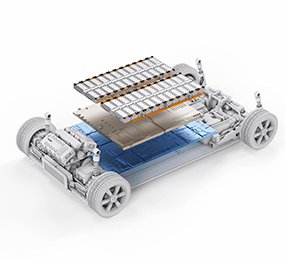

The burgeoning electric vehicle market necessitates sustainable solutions for managing end-of-life batteries. Recovering and reprocessing critical battery materials like lithium, cobalt, and nickel is crucial for minimizing environmental impact and ensuring resource security.

Several strategies are crucial for effective recovery and reprocessing:

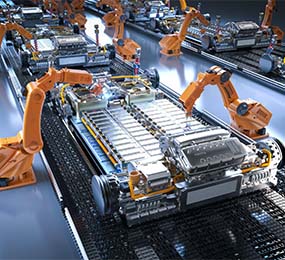

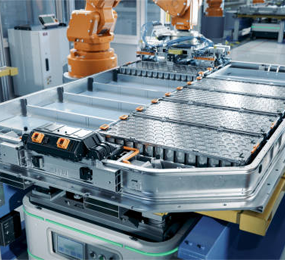

- Advanced Recycling Technologies: Investing in research and development of innovative recycling technologies, such as hydrometallurgical and pyrometallurgical processes, is paramount. These technologies aim to efficiently extract valuable materials while minimizing energy consumption and environmental impact.

- Closed-Loop Supply Chains: Establishing closed-loop supply chains that connect battery manufacturers, recyclers, and end-users is essential. This ensures the smooth and efficient flow of end-of-life batteries back into the production process.

- Government Incentives and Regulations: Implementing policies that incentivize battery recycling, such as subsidies, tax breaks, and extended producer responsibility programs, can significantly boost the economic viability of recycling operations.

- Public-Private Partnerships: Fostering collaboration between industry, academia, and government is crucial for driving innovation, sharing knowledge, and developing best practices in battery recycling.

By implementing these strategies, we can create a sustainable circular economy for battery materials, reducing reliance on primary resource extraction, minimizing environmental impact, and ensuring a secure supply of critical materials for future generations.

Visit our website to know more: https://www.leadventgrp.com/events/2nd-annual-electric-vehicle-battery-and-recycling-forum/details

For more information and group participation, contact us: [email protected]

Leadvent Group - Industry Leading Events for Business Leaders!

www.leadventgrp.com| [email protected]