Submarine transmission cable installation tends to be costly and challenging. The life cycle of a submarine cable could last about ten years and the technical interventions for its repairs and maintenance tend to be expensive and complicated. This is why it involves the coordinated effort of a lot of specialized professionals such as power system engineers, geologists, geophysicists and more. This installation happens in phases: - Selection of the proposed area for installation - Securing permission from relevant authorities - Surveying the selected area - Cable system design to be compatible with this area - Laying the cable - Notifying other marine users about the cable's position

Selection of the proposed area for installation

When selecting a potential location, we consider the following: - Landing Points, Territorial waters, Contiguous Zones (CZ) and Exclusive Economic Zones (EEZ) i.e. the Maritime Boundaries; - Cable selection; - Branching Unit deployments; - Geopolitics – Contested Areas; - Burial requirements; - Whether the cable landings can be made directly or have to be pre-laid; - Permitting & Fisherman Negotiations; and - Natural and manmade obstacles/hazards such as weather conditions prevailing, currents, seabed conditions, Mineral and/or Oil & Gas exploration, Pipelines, other submarine cables, areas of environmental concern, conservation area etc.

Securing permission from relevant authorities

When the route has been selected and designed, government agencies, other seabed stakeholders and authorities will be engaged in the acquisition of permits for the cable system.

Surveying the selected area

This is known as a route survey and it's done to identify a safe route for the cable and confirm the assumptions made while selecting the provisional area for installation.

Laying the cable

https://www.youtube.com/watch?v=Gg1aFmsKQgk

This phase is executed by specialized structural engineers. Where possible, and necessary, the preferred option is to bury the cables under the sea bed. This will help protect the cable from potential damage by the ship's anchors or commercial fishing. There are various methods of doing this, but the one most often used is a cable plough. The cable is fed out of the rear of the ship and onto a plough that is towed, either by the cable ship or another ship following behind. The plough lifts a furrow of the seabed and the cable slides into this furrow, then after the plough passes the part of the seabed that was lifted, it is returned to the seabed on top of the cable.

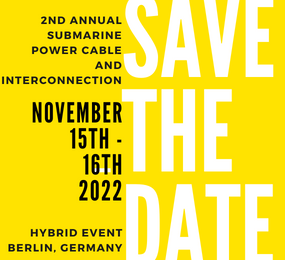

Michael Brooks is a Senior Executive at 4C Offshore Limited. At the Submarine Power Cable and Interconnection Forum, he's set to speak on: Installation and Long-term Risk Mitigation of Submarine Cable • Cable installation - drivers and continuing issues • HDVC Interconnector: real-time snapshot on installations to date • Financing / Insuring: key factors that need to be addressed to win back confidence • Insurance: an approach to installation due diligence has to change: the desktop study - practical follow-through.