Innovations in Submarine Power Cable Design and Manufacturing

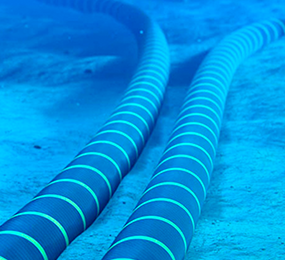

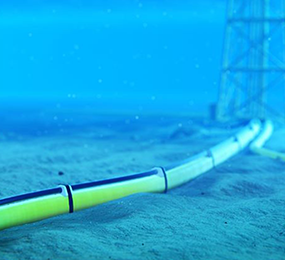

Innovations in submarine power cable design and manufacturing are driving significant advancements in the efficiency and reliability of underwater energy transmission. These cables are essential for connecting offshore wind farms, islands, and coastal regions to the mainland power grid, playing a crucial role in the expansion of renewable energy sources.

One major innovation is the development of high-voltage direct current (HVDC) cables, which offer superior efficiency over long distances compared to traditional alternating current (AC) systems. HVDC technology reduces energy loss and allows for the transmission of large amounts of electricity with minimal environmental impact. Additionally, advancements in insulation materials, such as cross-linked polyethylene (XLPE), have improved the durability and longevity of submarine cables, ensuring they can withstand harsh underwater conditions.

Manufacturing techniques have also evolved, with precision robotics and automation enhancing the production process. These methods ensure consistent quality and reduce the risk of defects, which is critical for the reliability of submarine power cables. Furthermore, the use of real-time monitoring systems during cable laying and operation helps in early detection of potential issues, allowing for timely maintenance and preventing costly downtimes.

These innovations not only support the growing demand for renewable energy but also contribute to the development of a more resilient and sustainable energy infrastructure.

Visit our website to know more: https://www.leadventgrp.com/events/4th-annual-submarine-power-cable-and-interconnection-forum/details

For more information and group participation, contact us: [email protected]

Leadvent Group - Industry Leading Events for Business Leaders!

www.leadventgrp.com| [email protected]