Impact of Manufacturing Processes on Extractables and Leachables Profiles

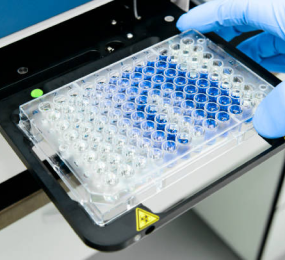

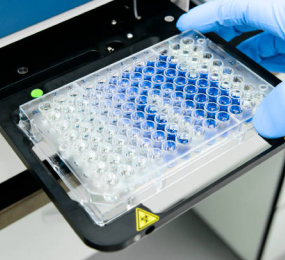

The impact of manufacturing processes on extractables and leachables (E&L) profiles is a critical consideration in the production of pharmaceuticals and medical devices. Extractables are chemicals that can be extracted from a material when in the presence of a solvent, while leachables are compounds that leach into a product under normal usage conditions. Both can significantly affect product safety and efficacy.

Manufacturing processes, including sterilization, molding, and chemical treatment, can alter the E&L profiles of materials used in medical products. For instance, high-temperature processes can induce chemical reactions that generate new extractable compounds. Similarly, certain solvents and cleaning agents used during manufacturing can leave residues that become leachables. Understanding these impacts is crucial, as the presence of harmful E&L compounds can lead to adverse health effects, regulatory non-compliance, and compromised product integrity.

To mitigate these risks, rigorous testing and validation of materials and processes are essential. Techniques such as gas chromatography-mass spectrometry (GC-MS) and liquid chromatography-mass spectrometry (LC-MS) are commonly employed to identify and quantify E&L compounds. By optimizing manufacturing processes and conducting thorough E&L assessments, manufacturers can ensure the safety and quality of their products, ultimately protecting patient health and meeting stringent regulatory standards.

Visit our website to know more: https://www.leadventgrp.com/events/global-extractables-leachables-forum/details

For more information and group participation, contact us: [email protected]

Leadvent Group - Industry Leading Events for Business Leaders!

www.leadventgrp.com| [email protected]